Junction boxes are electrical enclosures used to protect and contain electrical connections and wiring. They have several characteristic features, including:

Enclosure and Protection: Junction boxes are designed to provide a secure enclosure for electrical connections. They protect the wiring and connections from physical damage, moisture, dust, and other environmental factors. This helps ensure the safety and reliability of the electrical system.

Electrical Safety: Junction boxes enhance electrical safety by containing the connections within a designated space. They help prevent accidental contact with live wires or terminals, reducing the risk of electrical shocks or short circuits.

Wiring Organization: Junction boxes facilitate proper organization and management of electrical wiring. They allow for neat and structured arrangements of cables and connections, making it easier to troubleshoot and maintain the electrical system.

Connection Points: Junction boxes provide designated connection points where different wires or cables can be joined together. They often have terminal blocks or wire connectors inside the box to securely connect and insulate the wires.

Flexibility and Expansion: Junction boxes allow for flexibility and expansion of the electrical system. They can accommodate multiple wires, connectors, and accessories, making it possible to add or modify connections as needed.

Easy Access for Maintenance: Junction boxes typically have removable covers or panels, providing easy access for inspection, maintenance, and repairs. This allows electricians or technicians to safely work on the connections without exposing themselves to live electrical components.

Size and Capacity: Junction boxes are available in various sizes and capacities to accommodate different numbers of wires or cables. The size of the junction box should be chosen based on the number and size of the wires, as well as any additional space required for proper cable bending and insulation.

Material: Junction boxes are made from different materials, including plastic, metal (such as steel or aluminum), or fiberglass. The choice of material depends on factors like the application, environmental conditions, and specific requirements regarding durability, conductivity, or corrosion resistance.

Code Compliance: Junction boxes should meet relevant electrical codes and standards to ensure compliance with safety regulations. It is important to use junction boxes that are approved for the specific application and are installed according to the appropriate electrical codes.

There are several types of junction boxes available, each designed for specific applications and installation requirements. Here are some common types:

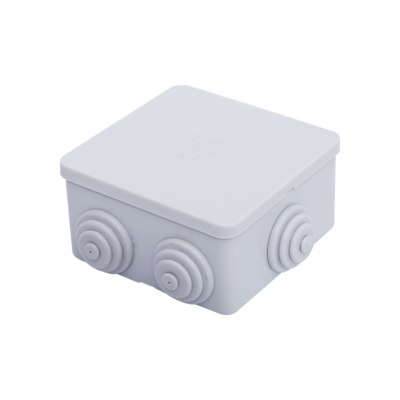

Plastic Junction Boxes: Plastic junction boxes are lightweight, affordable, and easy to work with. They are commonly used in residential and light commercial applications. Plastic junction boxes are non-conductive and provide good protection against moisture and corrosion.

Metal Junction Boxes: Metal junction boxes, such as steel or aluminum, offer enhanced durability and protection. They are often used in industrial or heavy-duty applications where ruggedness and resistance to impacts or fire are required. Metal junction boxes may provide better electromagnetic shielding and are suitable for environments with high electrical noise or interference.

Weatherproof Junction Boxes: Weatherproof junction boxes are designed to withstand exposure to outdoor elements. They are typically made of durable materials, such as plastic or metal, with seals or gaskets to provide protection against moisture, dust, and UV radiation. Weatherproof junction boxes are commonly used in outdoor electrical installations or areas with high humidity.

Surface-Mounted Junction Boxes: Surface-mounted junction boxes are installed on the surface of walls, ceilings, or other surfaces. They are visible and accessible, making them suitable for applications where the wiring connections need to be easily reached for maintenance or modifications.

Flush-Mounted Junction Boxes: Flush-mounted junction boxes are recessed into the wall or ceiling, resulting in a more concealed and aesthetically pleasing installation. They provide a neater appearance and are commonly used in new construction or renovation projects.

Underground Junction Boxes: Underground junction boxes are designed for buried or underground applications. They are specifically engineered to withstand soil pressure, moisture, and other underground conditions. These boxes are commonly used for outdoor lighting, irrigation systems, or underground electrical wiring.

Pull Boxes: Pull boxes, also known as splice boxes, are larger junction boxes that provide extra space for making wire connections and splices. They are typically used in applications where multiple conduits or cables converge, requiring additional room for wiring management and accessibility.

Electrical Panel Enclosures: Electrical panel enclosures are large junction boxes used for housing circuit breakers, switches, and other electrical components. They serve as the central distribution point for electrical power in a building or facility.